Discover the WFE V2 Mechanical

An innovative and sustainable solution for water purification through solar distillation

Learn More →Transform Raw Water into Drinking Water

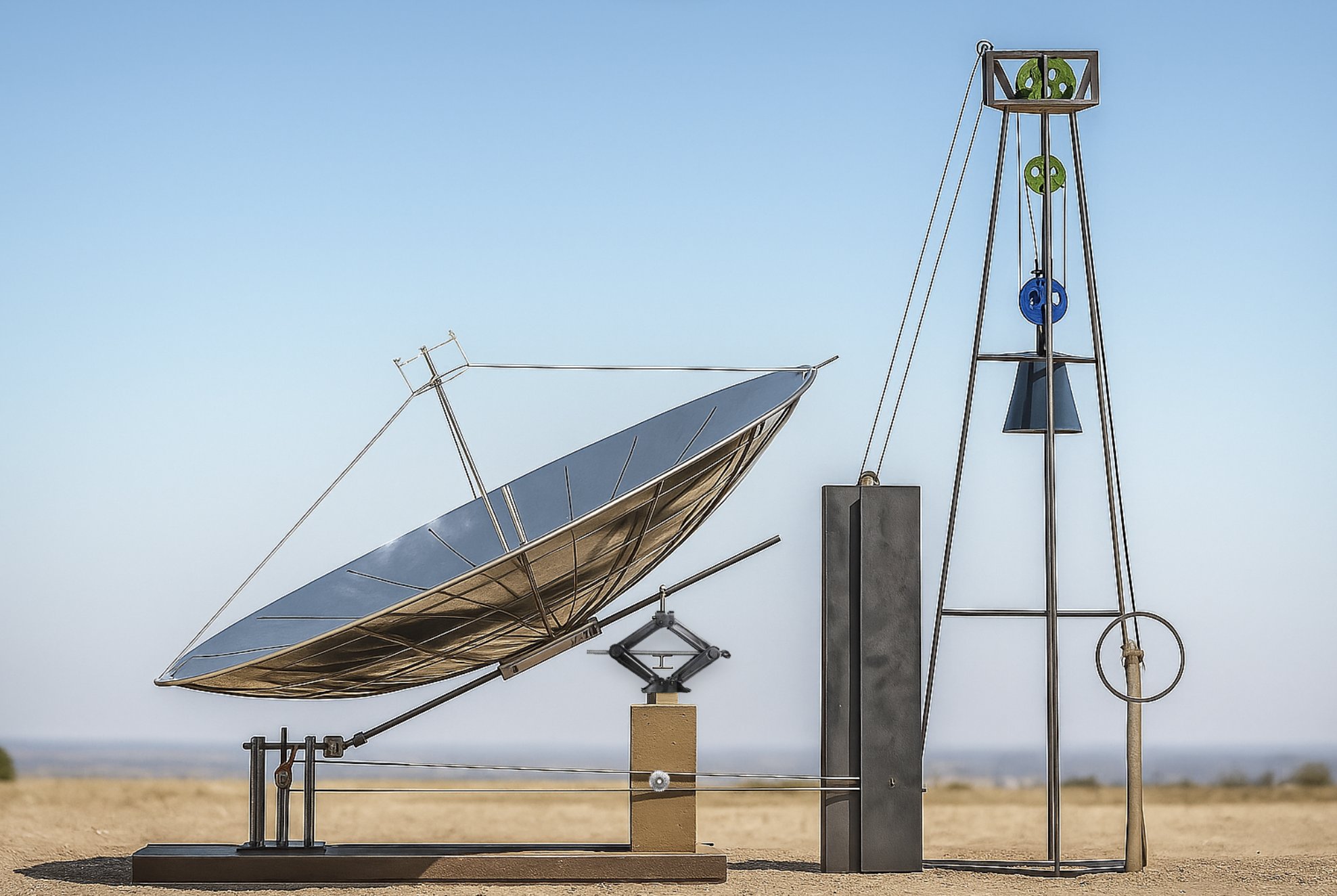

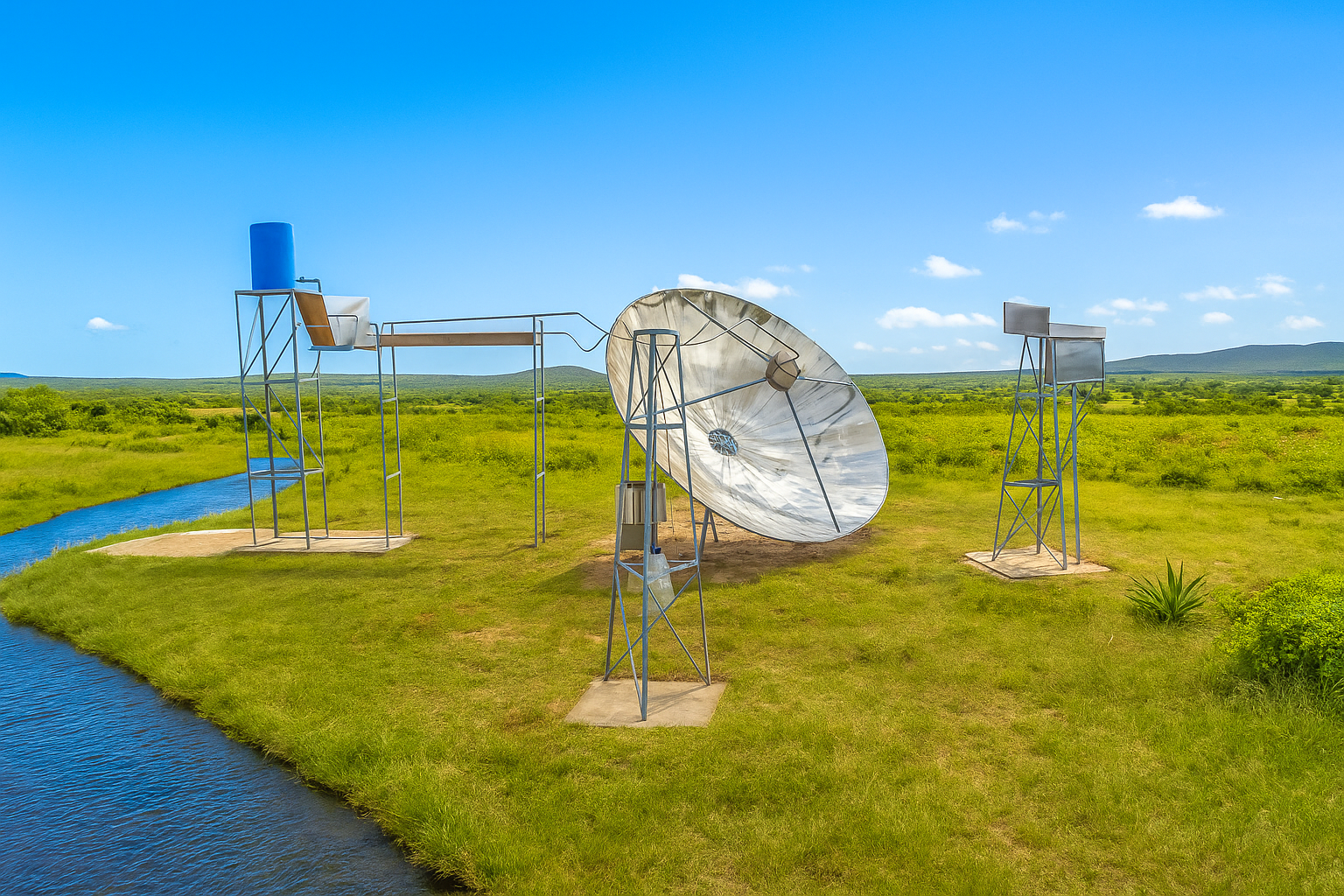

The V2 System harnesses concentrated solar energy to purify raw water or desalinate seawater. This fully mechanical system relies on a clockwork mechanism to adjust the solar concentrator’s position, tracking the sun throughout the day based on the month and year.

100% Solar Powered

Operates solely on thermal solar energy, eliminating dependency on rare materials and providing a 100% sustainable, clean, and renewable solution.

Fully Mechanical System

The absence of electronics ensures enhanced durability, making the system suitable for extreme or remote environments.

Drinking Water Production

Designed to produce up to 200L of drinking water from raw or seawater. The process also recovers salt crystals from desalination, ideal for local communities and NGOs.

Innovation and Unique Benefits

1 Energy Efficiency Optimization

Preheating of the primary tank is facilitated by the condenser and thermal generator.

The condenser serves a dual purpose: it transforms water vapor into liquid by contacting a naturally cooled pipe with incoming cold raw water. This contact rapidly lowers the pipe’s temperature, causing immediate condensation of the vapor.

In parallel, the thermal generator uses mirrors to focus sunlight onto a metal drum containing raw water. Solar energy is absorbed by the drum’s walls, heating them through radiation. The heat is then transferred to the water via conduction through the metal and distributed within the liquid by natural convection, preparing the water for the distillation cycle.

This closed-loop system recovers and reuses heat, significantly increasing energy efficiency while minimizing losses.

2 Cylindro-Parabolic Collector

The cylindro-parabolic collector is a key component in preheating. As water exits the first drum, it flows through a pipe positioned at the focal line of this curved mirror.

The device concentrates sunlight onto the pipe, heating the water by an additional 10 to 20°C before it enters the distiller.

This thermal gain, achieved solely through solar energy, enhances the system’s overall efficiency by reducing the energy required for vaporization.

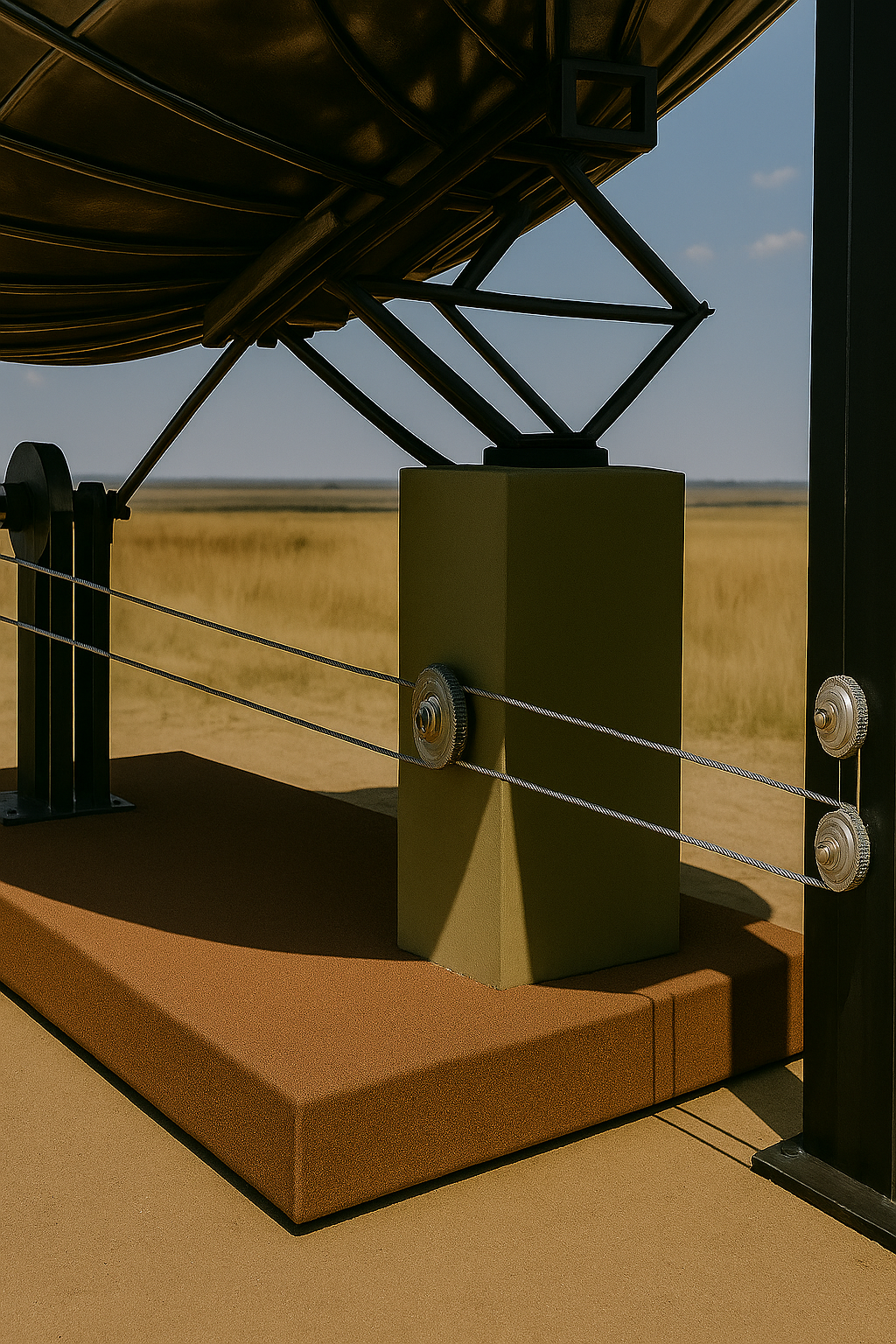

3 Advanced Mechanical Solar Tracking

This mechanical solar tracking system uses a clock driven by a suspended weight to gradually orient the solar concentrators throughout the day. Operating without any electrical power, it provides 10 hours of autonomy per cycle with a mechanically determined constant rotation speed. Solar alignment is calibrated based on latitude, season, and the initial orientation of the setup, ensuring optimized thermal output for distilled water or solar energy production.

Features of the System’s Mechanical Clock

- Gravity-Controlled Escapement Mechanism – The clock is powered by the slow descent of a suspended weight. This weight gradually releases potential energy, converted into steady rotation through a gear system.

- Fixed-Ratio Gear Transmission – A gear train determines the rotation speed, ensuring consistent movement of the solar structure at a predefined rate, calibrated to the sun’s apparent motion.

- Assisted Manual Rewind with Multiplied Pulley – The system is designed for daily rewinding with minimal effort using a simple or multiplied pulley, allowing a single person, even a child, to reset the weight easily.

Mechanical Adjustment and Control Components

- Angular Locking Pin – Allows precise locking or resetting of the parabolic dish’s angular position at the start of each daily cycle, ensuring a stable reference point for accurate solar tracking.

- Automatic Clutch Hub – Transmits the clock’s slow rotation to the concentrator and disengages automatically when the crank is turned in reverse.

- Seasonal Adjustment via Mechanical Clutch – A mechanism to manually adjust the main axis tilt of the concentrator based on solar declination, optimizing the angle of incidence for latitude and season.

- Multiplied Crank for Rewinding – The weight rewinding system is assisted by a crank coupled with a pulley, enabling low-effort, precise, and controlled rewinding without mechanical jolts or overload.

Energy: Counterweight

- Suspended Weight – Provides the gravitational energy needed to power the entire clock mechanism.

- Pulley System – Enables the weight to be raised daily to restart the system.

4 Solar Parabolic Concentrator

The solar parabolic concentrator acts as a large curved mirror, capturing sunlight throughout the day and focusing it onto the base of the distiller. This convergence system maximizes the internal temperature, promoting rapid vaporization of raw water without external energy.

Materials are designed to withstand wind, corrosion, and high temperatures.

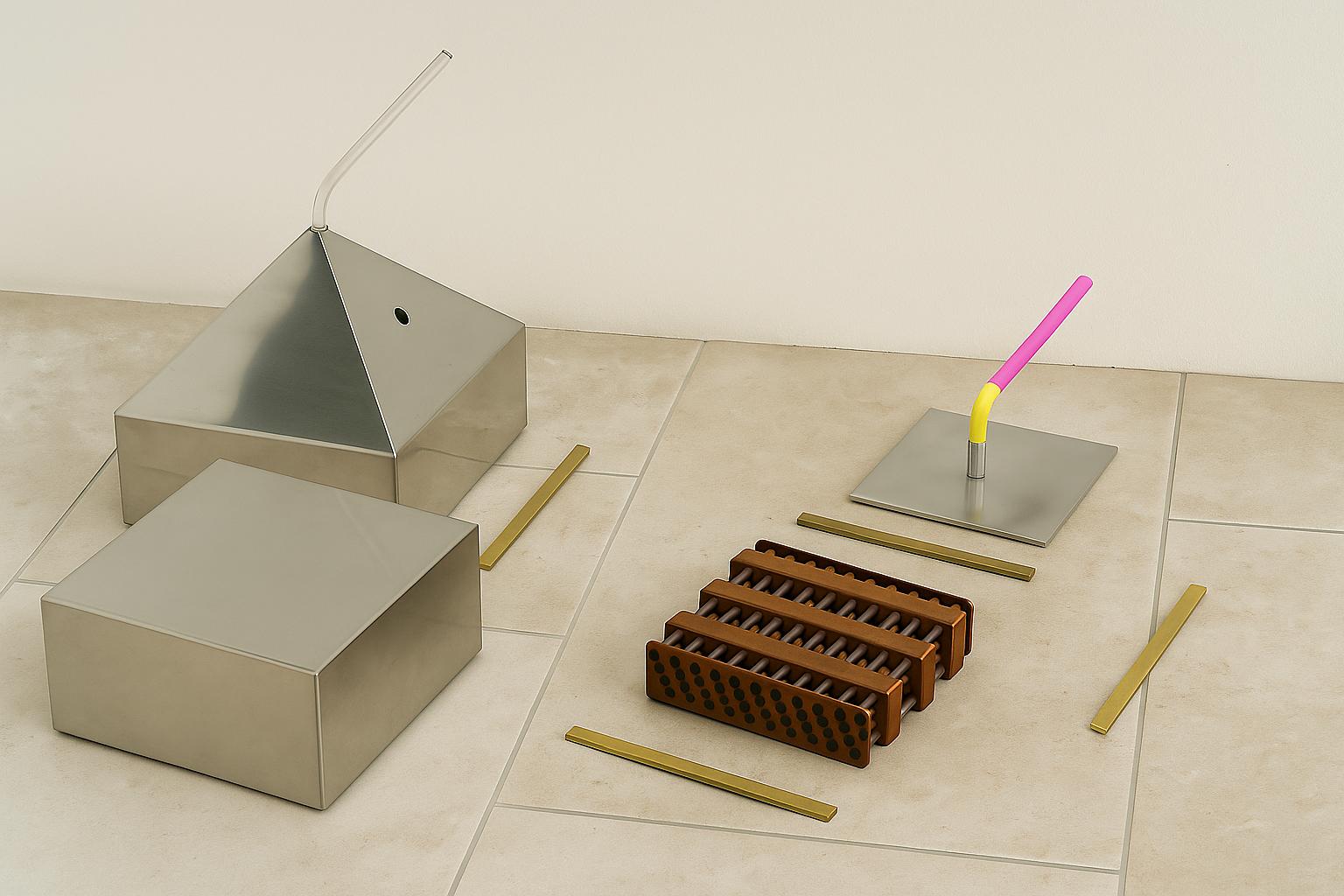

5 The Pyramid or Distiller

The distillation pyramid is the heart of the system, where raw water—whether salty or fresh—is evaporated.

Water is distributed drop by drop through a nozzle above heating tubes inside the pyramid. These tubes, heated by conduction, contain high-thermal-capacity materials like molten salts, which store heat temporarily and ensure stable heat release even during intermittent sunlight.

The water evaporates instantly upon contact with the hot surfaces, and the vapor is naturally directed to a central chimney, which channels it to the condensation unit.

Technical Specifications

| Feature | Value |

|---|---|

| Production Capacity | 120-250 liters/day, depending on weather conditions |

| Energy Source | Thermal solar energy |

| Integrated Technologies | Mechanical solar tracking based on geographic coordinates, azimuth, and seasons |

| Overall Dimensions | Installation area: 150 m², Height: 3 meters |

| Weight | ~700 kg |

| Operating Conditions | Shade-free terrain |

| Operating Temperature | Up to 700°C in clear weather and warm seasons, without clouds |

How It Works

Water Supply

Raw water, whether fresh or salty, is channeled to an elevated tank, leveraging gravity for natural, energy-efficient flow. This ensures a consistent and effective supply to initiate the solar purification process.

Preheating

The condenser preheats the raw water. This water is further preheated by solar reflection from the thermal generator as it passes through the condenser.

Solar Tracking

The solar tracking system adjusts the concentrators’ orientation based on the project’s longitude, latitude, and their position relative to the distiller.

Distillation

Inside the distiller, water is distributed drop by drop via a nozzle onto a heating radiator, enabling immediate vaporization upon contact.

Thermal Storage

In adverse weather conditions, the system relies on thermal storage using molten salts to maintain steam production.

Heat Recovery

The cylindro-parabolic collector focuses solar rays onto a central conduit through which raw water flows, reheating it before entering the distiller.

Condensation

Vapors are directed to the condenser, where they transform into liquid water.

Collection of Distilled Water

Purified water is collected in a final tank and remineralized for consumption.

V2 System Performance

WFE V2 Mechanical DIY Open Source

This open-source version is designed to be built with locally available materials, making construction accessible even in resource-limited regions. Each component comes with a SolidWorks file in PDF format and a product sheet detailing recommended materials, dimensions, and possible alternatives.

Download the resources below to start building your own WFE V2 Mechanical DIY. These documents are optimized for simple, cost-effective fabrication while maintaining system performance.

⚠️ Warning – Open Source Project

This project is a fully operational industrial system, offered as a DIY (Do It Yourself) version. We designed the DIY version to be as accessible as possible, using readily available materials like bicycle wheels, chains, hubs, or cranksets. However, its design remains complex.

Reproduction requires advanced knowledge and skills in fluid mechanics, geodesy, thermodynamics, optics, chemistry (phase transitions), material physics, precision clockmaking, and material work (welding, fine cutting, mechanical fitting, high-temperature sealing, etc.).

We disclaim any liability for damages due to improper use (strict safety rules must be followed), misinterpretation, or incorrect replication of the device. Ensure you understand the principles involved and have all necessary legal authorizations before attempting construction.

| Component | Description | Download |

|---|---|---|

| WFE V2 Mechanical DIY Device | General guide for the WFE V2 Mechanical DIY device | General Technical Guide |

| Thermal Generator | Metal drum with mirrors for solar preheating | 2D Plan Technical Guide |

| Cylindro-Parabolic Collector | Curved mirror for heating water before distillation | 2D Plan Technical Guide |

| Mechanical Clock | Solar tracking system with pendulum and counterweight | 2D Plan Technical Guide |

| Solar Parabolic Concentrator | Mirror concentrating solar rays toward the distiller | 2D Plan Technical Guide |

| Solar Distiller | Vaporization chamber with thermal salt radiator | 2D Plan Technical Guide |

| Load Support | Support for the load | 2D Plan Technical Guide |

| Condenser | Vapor liquefaction conduit with cooling and heat transfer | 2D Plan |

Ready to Transform Your Water Access?

Contact Niris today to learn more about the WFE V2 Mechanical.

Contact Us →